| Place of Origin: | Zhejiang |

| Brand Name: | Rubber Conveyor belt |

| Model Number: | EP/NN/C |

| Certification: | Iso |

| Minimum Order Quantity: | 10meter |

| Price: | $10/meter |

| Packaging Details: | Outer is packed with one ply water-proof PP fabric |

| Delivery Time: | 10-30DAYS |

| Payment Terms: | FOB |

| Supply Ability: | 100000meter/month |

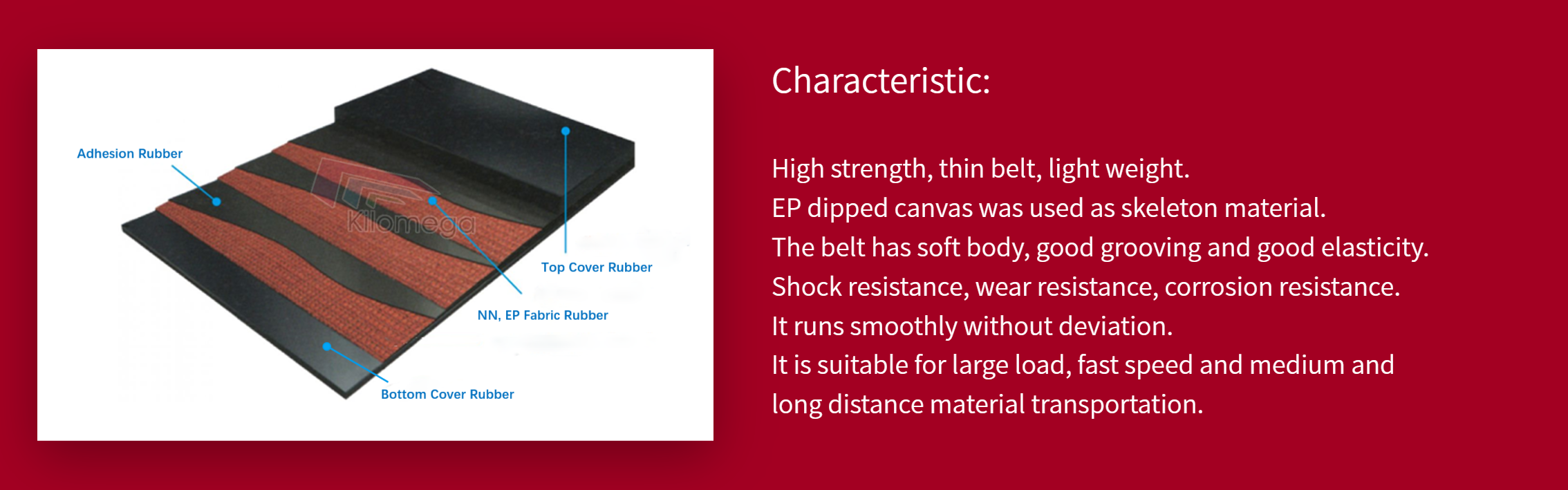

Fabric conveyor belts are suitable for medium and long distances, heavy loads, high Rapid material transportation, widely used in metallurgy, construction,

Quarry, electric power, chemical industry and other industrial application scenarios

| NN fabric | EP fabric |

| High stability | Low elongation |

| Short pulley diameter | Strong anti-shock |

| High heat resistance | Excellent adhesive force to rubber |

| Strong anti-shock | High stability |

| Excellent adhesive force to rubber | Temperature≤140ºC |

| / | (It will decompose over 140ºC) |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

It is suitable for conveying high temperature solid materials like sintering ore, coke, cement clinker, etc. which is used in metallurgical, cement

chemical industry and so on.

Developed new structure carcass materials will reduce the strength loss of heat aging during running, and thus will extend the working life.

The cover uses superior ethylene-propylene rubber or halogenate rubber which will enhance the high temperature resistant property

of the rubber and reduce the loss of heat aging.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil resistant conveyor belts select the NBR with excellent oil resistant properties as the covers. The reinforced materials can be selected according

to customers' requirements. It's suitable for conveying oily materials or the environment that exposure to a variety of working oil.

Low rate of volume change / High maintenance of strength / Wide application ranges

|

It's especially used in aboveground coal washeries, power plants, and non-coal underground mining. The safety meets GB10822.

The product is made of nylon canvas or EP canvas and finished through the processes of calendering, assembling, vulcanizing, etc.

The unique formula enables it to work continuously in a flammable environment.

| Grade | Tensile strength min (ISO37) Mpa |

Elongation at break min (ISO37) % |

Abrasion Max. (IS04649) mm |

| D | 18 | 450 | 200 |

| L | 14 | 400 | 250 |

| Items | Flame resistant grade | |

| K2 | K3 | |

Duration of flame |

The total duration of flame of 6 test pieces with covers is less than 45S,any individual test piece does not exceed 15 S |

Average value of duration of flame of 3 test pieces with covers does not exceed 60S |

| Anti-static property | ≤3×108Ω | |

Reapperance |

There should be no reappearance of flame on any test piece |

|

Fabric cord resistant conveyor belts are suitable for conveying materials outdoors in freezing area, cold storage and etc.

The product selects nylon canvas or EP canvas as carcass. Cover rubber selects a blend of NR and BR, which has the properties of high elasticity, shock resistance, cold resistance and etc. It can work normally under the conditions of -60oC.

| Grade | Tensile strength min (ISO37) Mpa |

Elongation at break min (ISO37) % |

Abrasion esistance max. (1S04649) mm |

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| L | 15 | 350 | 200 |

| Tensile cold-resistant coefficient C1(-45ºC) |

≥0.3 | ||

| lensile cold-resistant coefficient C2(-50ºC |

≥0.2 | ||

| Note:C1-working temperature-45ºC~60ºC;C2-working temperature-60ºC~60ºC | |||

Fabric pipe conveyor belt is a new type of conveying belt which uses EP/NN as carcass, high elastic, high anti-abrasive and high strength rubber as working surface. It's mainly used in conveying materials which are easily polluted like power, granular materials, etc. when working, the rubber belt changes its form from flat to U shape and finally to pipe, folding the materials and realizing the process of enclosed conveying.

Enclosed conveying of materials, protecting both the materials and the environment.

Steep angled conveying, the conveying angle can reach 30° usually.

Conveying line can be arranged according to the curve of space.

| Strength (KN/m) |

No of plies |

CarcasS type |

Belt width(mm) | ||||||||||||||||

| 300 | 400 | 500 | 600 | 750 | 800 | 930 | 1000 | 1050 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 3000 | |||

| 160 | 2 | NN/EP | |||||||||||||||||

| 250 | 2~3 | NN/EP | |||||||||||||||||

| 315 | 2~4 | NN/EP | |||||||||||||||||

| 400 | 2~4 | NN/EP | |||||||||||||||||

| 500 | 2~5 | NN/EP | |||||||||||||||||

| 630 | 3~6 | NN/EP | |||||||||||||||||

| 800 | 3~6 | NN/EP | |||||||||||||||||

| 1000 | 3~6 | NN/EP | |||||||||||||||||

| 1250 | 3~6 | NN/EP | |||||||||||||||||

| 1400 | 3-6 | NN/EP | |||||||||||||||||

| 1600 | 4~6 | NN/EP | |||||||||||||||||

| 2000 | 4~6 | NN/EP | |||||||||||||||||

| 2500 | 5~6 | NN/EP | |||||||||||||||||

| 3150 | 5~6 | NN/EP | |||||||||||||||||

| Nominal pipe diameter mm |

φ150 | φ200 | φ250 | φ300 | φ350 | φ400 | φ500 | φ600 | φ700 | φ800 |

| Width mm | 600 | 800 | 1000 | 1100 | 1300 | 1600 | 1850 | 2250 | 2450 | 2800 |

In accordance with HG4224-2011 standard

| Grade | Tensile strength min. Mpa |

Elongation at break min. % |

Abrasion Max. mm² |

| H | 25 | 450 | 120 |

| D | 18 | 400 | 90 |

| T1/T2 | 10 | 300 | 200 |

| Ozone resistant test condition:50pphm,40±2ºC,elongation:20%,time 96hours,no cracks T1-heat resistant 100C work condition,T2-heat resistant 125Cwork condition |

|||

The values will help to determine the appropriate cover compound for the application or for the materials carries Reliable assessment of the behavior of the covers in service for wear and cut resistance cannot be determined from tensile strength, and abrasion values alone.

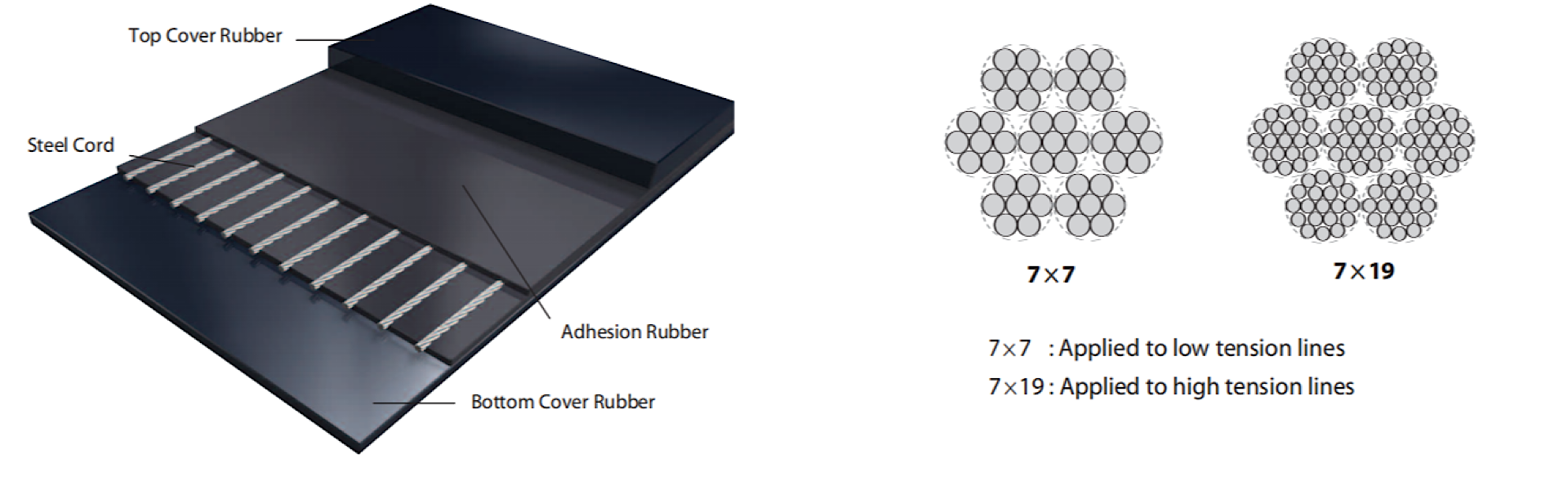

The steel wire rope core conveyor belt is a rubber conveyor belt with steel wire as its skeleton. It has the advantages of high tensile strength, good impact resistance, long service life, small use elongation, good grooving, good flexibility resistance, and is suitable for long-distance, large-distance and high-speed conveying materials. The product is composed of core glue, wire rope, covering layer and side glueaterials.

| Main Technical Parameters of Steel Wire Core Conveyor Belt in Germany | |||||||||||||||

| project | Number of wire rope roots | Width specification/mm | |||||||||||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | ||||||||

| Minimum Tensile Strength N/mm | Wire rope diameterd(maximum) | Rope distance±1.5mm | Covering glue thickness (minimum) | width | |||||||||||

| Width specification/mm | |||||||||||||||

| ±5 | ±7 | ±8 | ±10 | ±10 | ±12 | ±12 | ±14 | ||||||||

| St1000 | 1000 | 4.1 | 12 | 4 | 39 | 51 | 64 | 81 | 97 | 114 | 131 | 147 | |||

| St1250 | 1250 | 4.9 | 14 | 4 | 34 | 44 | 55 | 69 | 84 | 98 | 112 | 127 | |||

| St1600 | 1600 | 5.6 | 15 | 4 | - | - | 50 | 64 | 77 | 90 | 104 | 117 | |||

| St2000 | 2000 | 5.6 | 12 | 4 | - | - | 64 | 81 | 97 | 114 | 131 | 147 | |||

| St2500 | 2500 | 7.2 | 15 | 5 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| St3150 | 3150 | 8.1 | 15 | 5.5 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| St3500 | 3500 | 8.6 | 15 | 6.5 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| St4000 | 4000 | 8.9 | 15 | 7 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| Performance Grade of Covering Rubber | |||

| Grade code | tensile strength,Mpa≥ | Elongation at break,%≥ | Wear volume,mm³≤ |

| D | 18 | 400 | 90 |

| H | 25 | 450 | 120 |

| L | 20 | 400 | 150 |

| P | 14 | 350 | 200 |

| notes: D-Strong Wear Working Conditions;H-Strong splitting working conditions;L-General working conditions |

|||

| P-Oil-resistant, heat-resistant, acid-alkali-resistant, cold-resistant and general non-flammable conveyor belts | |||

| Performance Grade of Covering Rubber | |||

| Executive standard DIN22131standard | |||

| Performance grade | tensile strength | Tensile ratio at break | Wear volume |

| <=mm³ | |||

| W | 18 | 400 | 90 |

| X | 25 | 450 | 120 |

| Y | 20 | 400 | 150 |

| K* | 20 | 400 | 200 |

| notes:*Suitable for general flame retardant conveyor belt conforming to DIN22103.Its covering glue meets the requirements of DIN22104 | |||

| Index Description | Strength between layers | Cover layer and fabric layer | |

| Thickness of cover layer ≤1.5mm | Thickness of cover layer>1.5mm | ||

| Sample average value | 4.5N/mm | 3.2N/mm | 3.5N/mm |

| Fabric material | Favric structure | Fabric code | No.of fabric plies | Width mm | Length m | Cover thickness mm | ||

| warp | weft | Top | Bottom | |||||

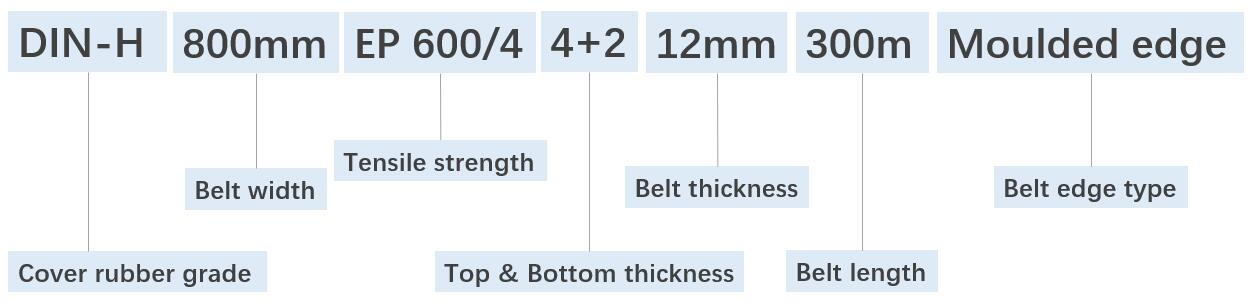

| Polyester canvas | polyester | Nylon of polyester | EP100 | 2-10 | 350-2000 | 10-400 | 2-12 | 1-5 |

| EP150 | 2-10 | 350-2000 | 10-400 | 2-12 | 1-5 | |||

| EP200 | 2-10 | 350-2000 | 10-400 | 2-12 | 1-5 | |||

| EP250 | 2-10 | 350-2000 | 10-400 | 2-12 | 1-5 | |||

| EP300 | 2-6 | 350-2000 | 10-400 | 2-12 | 1-5 | |||

| EP400 | 2-6 | 350-2000 | 10-400 | 2-12 | 1-5 | |||

| EP500 | 2-6 | 350-2000 | 10-400 | 2-12 | 1-5 | |||

| EP600 | 2-4 | 350-2000 | 10-400 | 2-12 | 1-5 | |||

Our friendly team would love to hear from you!