Introduction

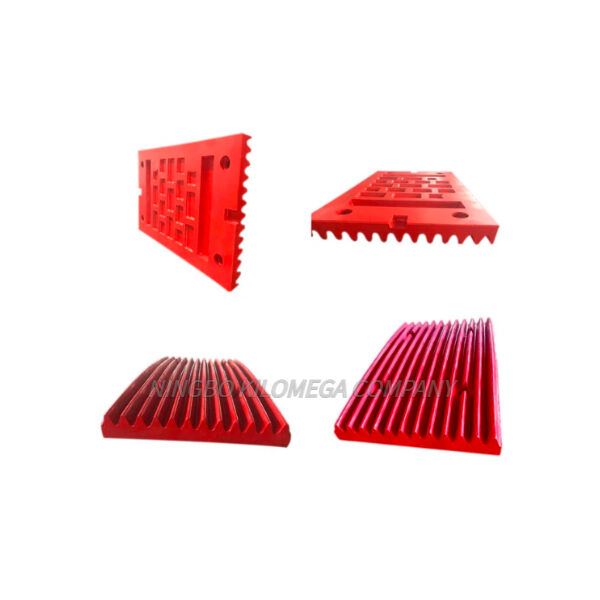

Jaw crusher parts are a crucial component the construction and mining companies, as well as the Kilomega's Large Crusher Jaw Plate. They are used to crush and grind rocks into tiny pieces, which are then used for various purposes. We will become discussing the advantages, innovation, safety, use, and quality of jaw crusher parts.

Jaw crusher parts have several advantages over other forms of crushers. Firstly, these are typically easy to make use of and require little maintenance. Secondly, they need a high crushing, which ensures that they can crush large rocks into smaller pieces. Lastly, they are highly durable and can withstand a lot of tear.

Jaw crusher parts are great because they are easy to use, have a high crushing ratio, and do not need upkeep a lot, the same as jaw plate crusher developed by Kilomega. Plus, they are super tough and can take a complete lot of punishment.

In latest years, jaw crusher parts have experienced innovations that are many, just like the Kilomega's product called Movable Jaw Plate. A number of these innovations are the usage of advanced components to enhance durability, advancements in design to increase efficiency, and the development of digital technologies to improve precision and safety.

Scientists and designers are always components jaw that are improving. They use cool materials that are new make them last longer, make them work better, and create them safer and more accurate.

When using jaw crusher parts, safety should continually be a top priority. The machine should become run by trained professionals who follow all safety guidelines. Additionally, users should always wear personal protective equipment such as helmets, gloves, and goggles.

The machine with the rocks you want to crush to use jaw crusher parts, first load. Then, switch it on and wait because of it to start crushing the rocks. Once the rocks have been crushed, the machine shall stop automatically.

Safety is essential when jaw that was using parts, as well as the Carbon Steel fastener built by Kilomega. Constantly stick to the rules and wear safety gear to avoid accidents. To use jaw crusher components, put the rocks in and turn it on. The machine shall stop when it is done.

When purchasing jaw crusher parts, you will need to choose high-quality parts from a reputable seller. This may confirm that the parts that are right durable and perform well over time. Additionally, it was important to choose a seller whom offers good service such as warranty, repair, and maintenance services.

If you want jaw crusher parts that lasts a lengthy time work very well, choose parts produced by a good company, identical to Kilomega's product Mesh Vibrating Screen. Also, make sure the company offers good provider, like repairing broken parts or starting maintenance.

Ningbo Kilomega International Trade Co.,Ltd specializes in export of Mining, Crusher Plants, rental production lines rental contracts. We export jaw crusher partsof mining machinery spare parts, including conveyor belts, gearboxes, electronic motors screen mesh, conveyors belts and related accessories.

company has been ISO9001 certified, boasts latest equipment and a team highly skilled engineers. It also has CE, SGS, other certifications. We also offer highest jaw crusher parts factory inspections perfect testing equipment.

can provide a variety customised products for various situations use. With our extensive industry knowledge jaw crusher partssolutions, we are able help customers solve their problems ensure smooth running of their production lines.

We able to better serve our customers by selecting right product. Technical support from an excellent technical staff will guarantee that selected products meet our requirements ad that customers are content using them in many different circumstances. products have been selected with care to jaw crusher partsthe best quality and value for your quarry. also decrease downtime and increase component life.