Rubber Mining Conveyor Belt: An Amazing Invention for Mining Industry.

The Rubber Mining Conveyor Belt is now a must-have for transporting materials from one point out another in the Mining industry. This innovative system revolutionized the way Mining companies operate, by way of its numerous advantages. We will explore the advantages, innovation, safety, use, and quality of the Kilomega conveyor rubber belt.

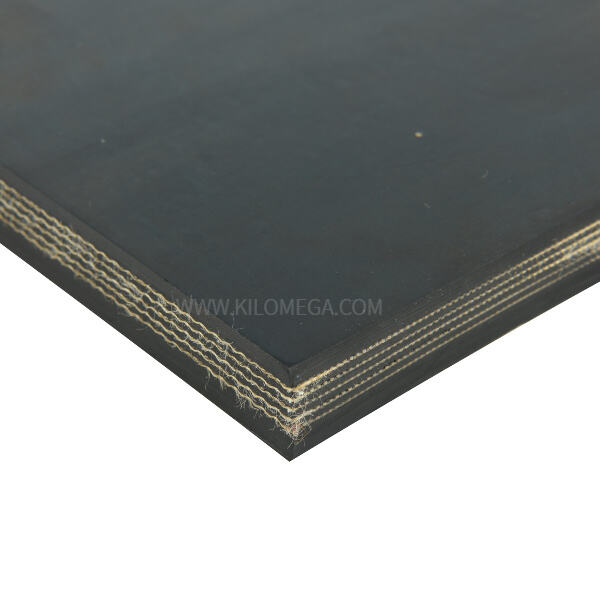

The primary feature of the rubber mining conveyor belt is its durability and toughness. The belt is constructed of high-quality rubber materials that can withstand harsh mining conditions, including temperature, dust, and rocks. This feature makes it cost-effective, as the belt has a longer lifespan compared to other traditional belts. Additionally, the Kilomega Ep Fabric Rubber Conveyor Belt has excellent adhesion levels, making it easy to handle heavy and bulky loads, thus increasing productivity.

The rubber mining conveyor belt has brought about a revolution of new opportunities in the mining industry. The belt has been instrumental in revolutionizing mine operations and enhancing worker safety. Compared to traditional belts, the rubber mining conveyor belt has integrated features that protect the operators' well-being. For instance, the Kilomega Conveyor Belt Rubber has fire-resistant properties to protect the workers and assets from fire damage. Additionally, the belt does not produce sparks when it comes in contact with metallic objects, eliminating the risk of igniting explosive materials.

The mining industry has been prone to high-risk accidents, especially when transporting materials from one point to another in the past. However, the Kilomega Rubber Mining Conveyor Belt is a game-changer in terms of safety. The belt is actually designed to prevent spillages, which significantly reduces the risk of falls and accidents. Additionally, the design of the rubber mining conveyor belt eliminates the need for manual handling. Therefore, employees can operate the belts using automated machinery, minimizing the risk of accidents due to human errors.

Using the rubber mining conveyor belt is uncomplicated and easy. Before operating the Kilomega Rubber Conveyor Mining Blet, it is essential to ensure that it is in good condition, free of cracks, tears, or any other damage. Once the belt is in top condition, it can be installed on the conveyor system, taking care to align it correctly. After installation, the belt must be tensioned correctly, ensuring that it is neither too tight nor too loose. The operator should follow the manufacturer's recommended operating parameters to ensure maximum productivity.

Based on understanding of entire industry allow us to better serve customers with the best product (Selected products). Our skilled experienced technical staff can make sure that the selected Rubber Mining Conveyor Beltmeet our specifications that customers are satisfied with diverse complex situations (Technical assistance). selection of products has been carefully considered to provide the highest value and performance for the quarry you are working with. They also reduce downtime and prolong the life of components.

have a range of products that can be customized suit various situations. With rich industry experience skilled solutions, we are able Rubber Mining Conveyor Beltissues customers ensure the efficient performance of their production lines.

business has been ISO9001 certified, boasts latest equipment, a team of highly Rubber Mining Conveyor Beltengineers. It also holds CE, SGS, other certifications. also offer 100% factory inspection and best testing equipment.

Ningbo Kilomega International Trade Co.,Ltd is specialized exporter of Mining, Crusher Plants production lines for Rubber Mining Conveyor Belt. export a wide assortment of mining equipment spare parts, including belt conveyors, gearboxes, screens for electronic motors, conveyor belts, other accessories.