позвони нам.

+86-13750670648пошлите нам.

[email protected]посетите нас

No.39, Huancheng West Road.Haishu.Ningbo, China

позвони нам.

+86-13750670648пошлите нам.

[email protected]посетите нас

No.39, Huancheng West Road.Haishu.Ningbo, China| Место происхождения: | Чжэцзян |

| Название бренда: | Галечный ремень |

| Номер модели: | EP/NN/C |

| Сертификация: | ИСО |

| Минимальное количество заказа: | 10метр |

| Цена: | $10/метр |

| Подробности упаковки: | Наружный слой упакован из однослойной водонепроницаемой ткани PP |

| Время доставки: | 10-30 дней |

| Условия оплаты: | FOB |

| Способность поставки: | 100000meter/месяц |

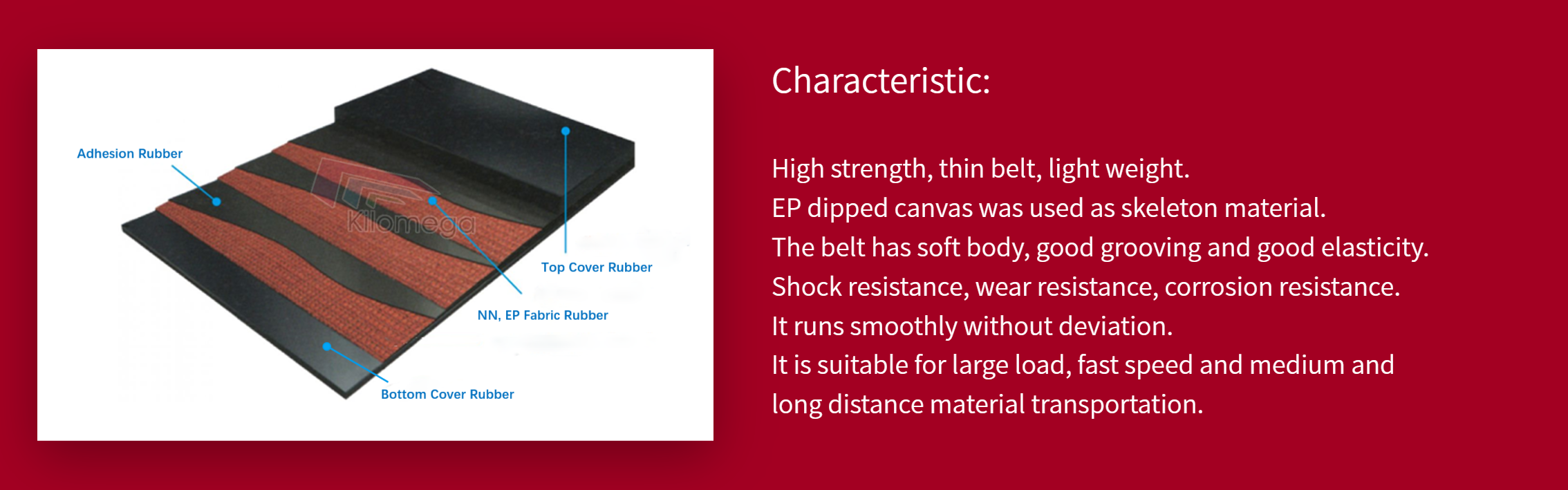

Тканевые транспортные конвейеры подходят для средних и дальних расстояний, больших нагрузок, высоких Быстрая транспортировка материалов, широко используется в металлургии, строительстве,

Карьер, электроэнергетика, химическая промышленность и другие производственные сценарии применения

| Ткань NN | Ткань EP |

| Высокая устойчивость | Низкое удлинение |

| Малый диаметр шкива | Высокая противосиловая прочность |

| Высокая теплостойкость | Отличная адгезия к резине |

| Высокая противосиловая прочность | Высокая устойчивость |

| Отличная адгезия к резине | Температура ≤ 140ºC |

| / | (Разлагается при температуре выше 140ºC) |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Подходит для транспортировки высокотемпературных твердых материалов, таких как обожженная руда, кокс, цементный клинкер и т.д., используемых в металлургии, цементной промышленности

химической промышленности и т.д.

Разработанные новые конструкционные материалы carcass снизят потерю прочности при тепловом старении во время работы, что увеличит срок службы.

Накладка изготовлена из качественного этилен-пропиленового каучука или галогенированного каучука, что повышает жаростойкие свойства

каучука и снижает потери от теплового старения.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Маслостойкие транспортные ленты выбирают НБР с отличными маслостойкими свойствами в качестве покрытий. Укрепляющие материалы могут быть выбраны согласно

требованиям заказчиков. Подходит для транспортировки маслянистых материалов или для сред, подверженных воздействию различных рабочих масел.

Низкий уровень изменения объема / Высокое сохранение прочности / Широкий диапазон применения

|

Особенно используется на наземных углеобогатительных фабриках, электростанциях и подземных горных работах неугольной отрасли. Безопасность соответствует ГБ10822.

Продукт изготовлен из нейлонового полотна или полотна ЭП и изготовлен путем каландрования, сборки, вулканизации и других процессов.

Уникальная формула позволяет ему непрерывно работать в горючей среде.

| Grade | Устойчивость к растяжению мин (ISO37) МПа |

Удлинение при перерыве мин (ISO37) % |

Износостойкость Макс. (IS04649) мм |

| Г | 18 | 450 | 200 |

| Л | 14 | 400 | 250 |

| Элементы | Класс пламенестойкости | |

| K2 | K3 | |

|

Продолжительность горения |

Общая продолжительность пламени 6 испытаний образцов с крышками меньше чем 45 секунд, любой отдельный образец не превышает 15 секунд |

Среднее значение продолжительности пламени 3 образцов с крышками не превышает 60 секунд |

| Противостатические свойства | ≤3×108Ω | |

|

Повторное появление |

Не должно быть повторного возникновения пламени на каком-либо испытательном образце |

|

Транспортерные ремни с текстильным кордом подходят для транспортировки материалов на открытом воздухе в зонах замерзания, холодильных камерах и т.д.

Продукция использует нейлоновое полотно или полотно EP в качестве каркаса. Для покрывающего резинового слоя используется смесь НК и БК, которая обладает свойствами высокой упругости, сопротивления удару, морозостойкости и т.д. Может работать нормально при температуре -60ºC.

| Grade | Устойчивость к растяжению мин (ISO37) МПа |

Деформация при ломаться мин (ISO37) % |

Износостойкость сопротивление макс. (1S04649) мм |

| H | 24 | 450 | 120 |

| Г | 18 | 400 | 100 |

| Л | 15 | 350 | 200 |

| Растяжимость морозостойкая коэффициент C1(-45ºC) |

≥0.3 | ||

| растяжимость морозостойкая коэффициент C2(-50ºC) |

≥0.2 | ||

| Примечание: C1 - рабочая температура -45ºC~60ºC; C2 - рабочая температура -60ºC~60ºC | |||

Тканевый трубчатый конвейерный ремень является новым типом транспортерного ремня, использующего EP/NN как каркас, с высокоупругой, износостойкой и высокопрочной резиной в качестве рабочей поверхности. Он主要用于 для транспортировки материалов, которые легко загрязняются, таких как порошок, гранулированные материалы и т.д. При работе резиновый ремень изменяет свою форму от плоской до U-образной формы и, наконец, становится трубой, заключая материал и реализуя процесс закрытой транспортировки.

Закрытая транспортировка материалов, защищая как материалы, так и окружающую среду.

Транспортировка под крутым углом, угол транспортировки может достигать 30°.

Линия транспортировки может быть размещена согласно кривой пространства.

| Прочность (кН/м) |

Нет из слои |

Каркас тИП |

Ширина ремня (мм) | ||||||||||||||||

| 300 | 400 | 500 | 600 | 750 | 800 | 930 | 1000 | 1050 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 3000 | |||

| 160 | 2 | NN/EP | |||||||||||||||||

| 250 | 2 ~ 3 | NN/EP | |||||||||||||||||

| 315 | 2~4 | NN/EP | |||||||||||||||||

| 400 | 2~4 | NN/EP | |||||||||||||||||

| 500 | 2~5 | NN/EP | |||||||||||||||||

| 630 | 3 ~ 6 | NN/EP | |||||||||||||||||

| 800 | 3 ~ 6 | NN/EP | |||||||||||||||||

| 1000 | 3 ~ 6 | NN/EP | |||||||||||||||||

| 1250 | 3 ~ 6 | NN/EP | |||||||||||||||||

| 1400 | 3-6 | NN/EP | |||||||||||||||||

| 1600 | 4 ~ 6 | NN/EP | |||||||||||||||||

| 2000 | 4 ~ 6 | NN/EP | |||||||||||||||||

| 2500 | 5 ~ 6 | NN/EP | |||||||||||||||||

| 3150 | 5 ~ 6 | NN/EP | |||||||||||||||||

| Номинальный трубка диаметр мм |

φ150 | φ200 | φ250 | φ300 | φ350 | φ400 | φ500 | φ600 | φ700 | φ800 |

| Ширина мм | 600 | 800 | 1000 | 1100 | 1300 | 1600 | 1850 | 2250 | 2450 | 2800 |

В соответствии со стандартом HG4224-2011

| Grade | Устойчивость к растяжению мин. МПа |

Деформация при ломаться мин. % |

Износостойкость Макс. мм² |

| H | 25 | 450 | 120 |

| Г | 18 | 400 | 90 |

| T1/T2 | 10 | 300 | 200 |

| Условия испытания на устойчивость к озону: 50pphm, 40±2ºC, удлинение: 20%, время 96 часов, без трещин T1 - теплостойкость при рабочей температуре 100°C, T2 - теплостойкость при рабочей температуре 125°C |

|||

Эти значения помогут определить подходящий состав покрытия для применения или для используемых материалов Надежная оценка поведения покрытий в эксплуатации с точки зрения износостойкости и сопротивления разрезанию не может быть определена только по показателям прочности на растяжение и износа.

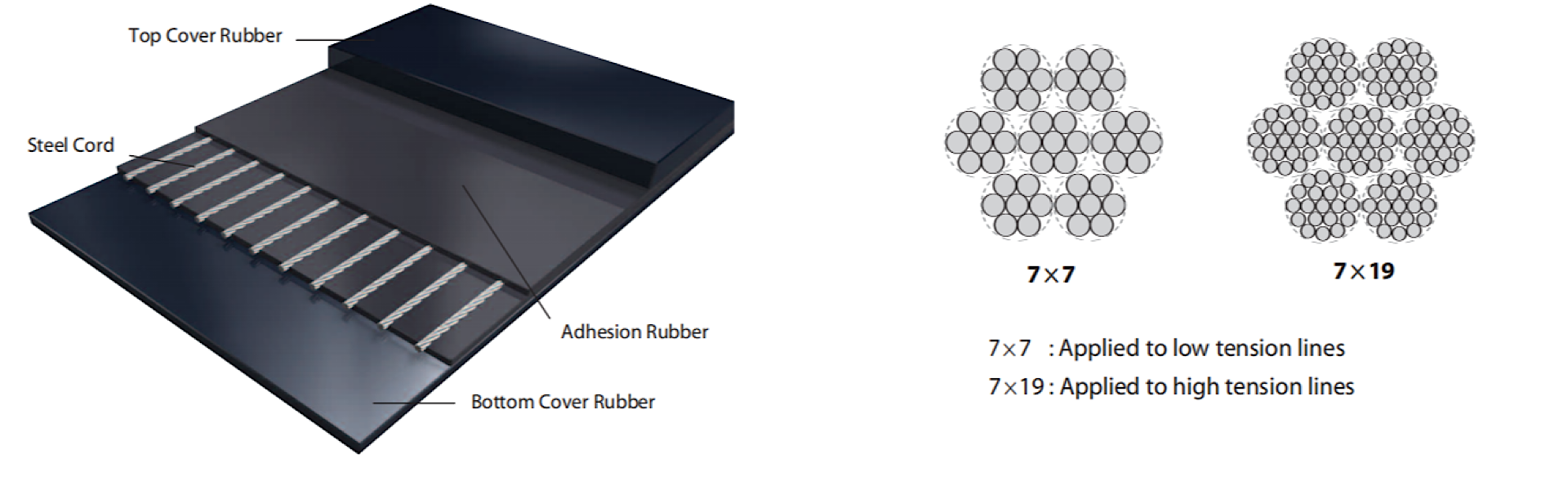

Ремень конвейера с стальной проволочной основой — это резиновый конвейерный ремень, в котором используется стальная проволока как каркас. Он обладает преимуществами высокой прочности на растяжение, хорошего сопротивления ударным нагрузкам, длительным сроком службы, небольшим удлинением при использовании, хорошим сопротивлением гибам, подходит для длинных дистанций, больших расстояний и высокоскоростной транспортировки материалов. Продукт состоит из клеевой основы, проволоки, покровного слоя и боковых материалов.

| Основные технические параметры конвейерного ремня с стальной проволочной основой в Германии | |||||||||||||||

| проект | Количество корней стальной проволоки | Ширина спецификации/мм | |||||||||||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | ||||||||

| Минимальная прочность на растяжение Н/мм | Диаметр стального троса d (максимум) | Расстояние между тросами ±1.5мм | Толщина покрывающего клея (минимум) | ширина | |||||||||||

| Ширина спецификации/мм | |||||||||||||||

| ±5 | ±7 | ±8 | ±10 | ±10 | ±12 | ±12 | ±14 | ||||||||

| СТ1000 | 1000 | 4.1 | 12 | 4 | 39 | 51 | 64 | 81 | 97 | 114 | 131 | 147 | |||

| ST1250 | 1250 | 4.9 | 14 | 4 | 34 | 44 | 55 | 69 | 84 | 98 | 112 | 127 | |||

| ST1600 | 1600 | 5.6 | 15 | 4 | - | - | 50 | 64 | 77 | 90 | 104 | 117 | |||

| СТ2000 | 2000 | 5.6 | 12 | 4 | - | - | 64 | 81 | 97 | 114 | 131 | 147 | |||

| ST2500 | 2500 | 7.2 | 15 | 5 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| ST3150 | 3150 | 8.1 | 15 | 5.5 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| ST3500 | 3500 | 8.6 | 15 | 6.5 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| СТ4000 | 4000 | 8.9 | 15 | 7 | - | - | - | 64 | 77 | 90 | 104 | 117 | |||

| Класс эксплуатационных характеристик покрывающей резины | |||

| Код класса | прочность на растяжение, Мпа ≥ | Длина при разрыве, % ≥ | Объем износа, мм³ ≤ |

| Г | 18 | 400 | 90 |

| H | 25 | 450 | 120 |

| Л | 20 | 400 | 150 |

| Р | 14 | 350 | 200 |

|

примечания: D-Сильный износ рабочих условий; H-Сильные разделяющие рабочие условия; L-Общие рабочие условия |

|||

| P-Маслостойкие, жаростойкие, кислото-щелочестойкие, холодостойкие и общие негорючие транспортерные ленты | |||

| Класс эксплуатационных характеристик покрывающей резины | |||

| Нормативный стандарт DIN22131стандарт | |||

| Класс производительности | устойчивость к растяжению | Предел прочности при растяжении | Объем износа |

| ≤ мм³ | |||

| В | 18 | 400 | 90 |

| X | 25 | 450 | 120 |

| Y | 20 | 400 | 150 |

| K* | 20 | 400 | 200 |

| примечания: * Подходит для общего противопожарной транспортерной ленты, соответствующей DIN22103. Ее покрывающий клей соответствует требованиям DIN22104 | |||

Наша дружелюбная команда будет рада услышать от вас!