razlog zašto se kaže da su remenice važne u prijenosu kretanja i sile u sustavu osovina. Počevši od industrijske primjene, uključujući strojeve, do predmeta koji se koriste u poljoprivredi, remenice se nalaze u mnogim industrijama. Vodič će stoga raspravljati o različitim vrstama Kolotura, učestalost njihove redovne uporabe kao i preporučenu učestalost održavanja remenica.

1. Vrste remenica

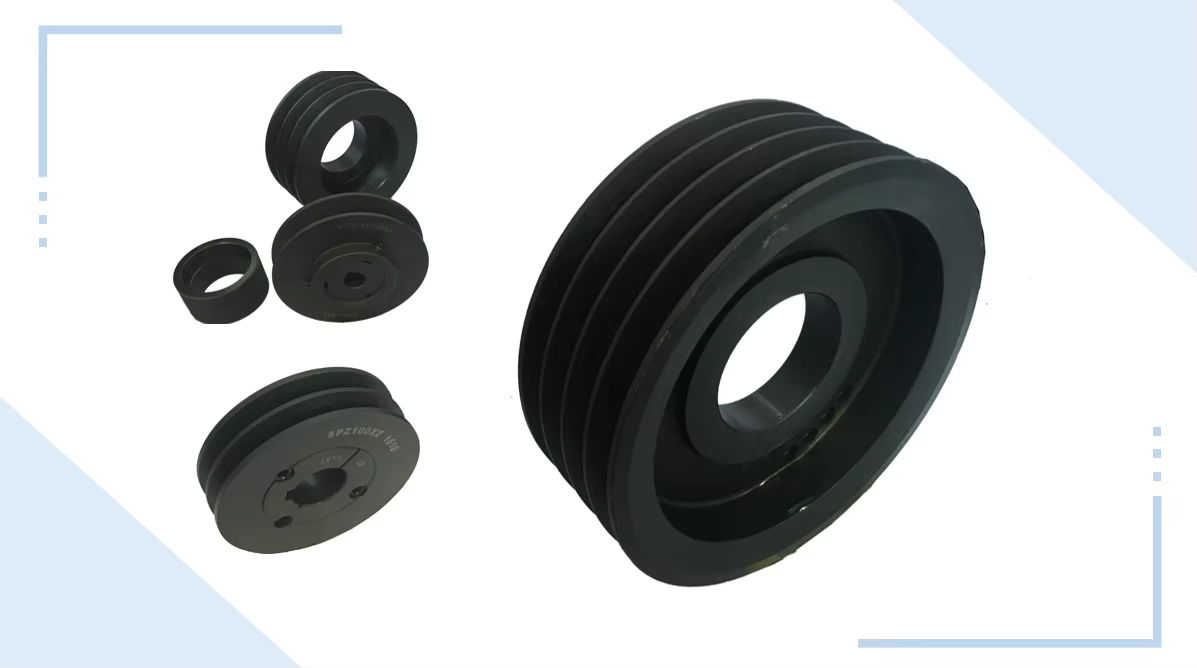

1.1 Standardne remenice s utorima

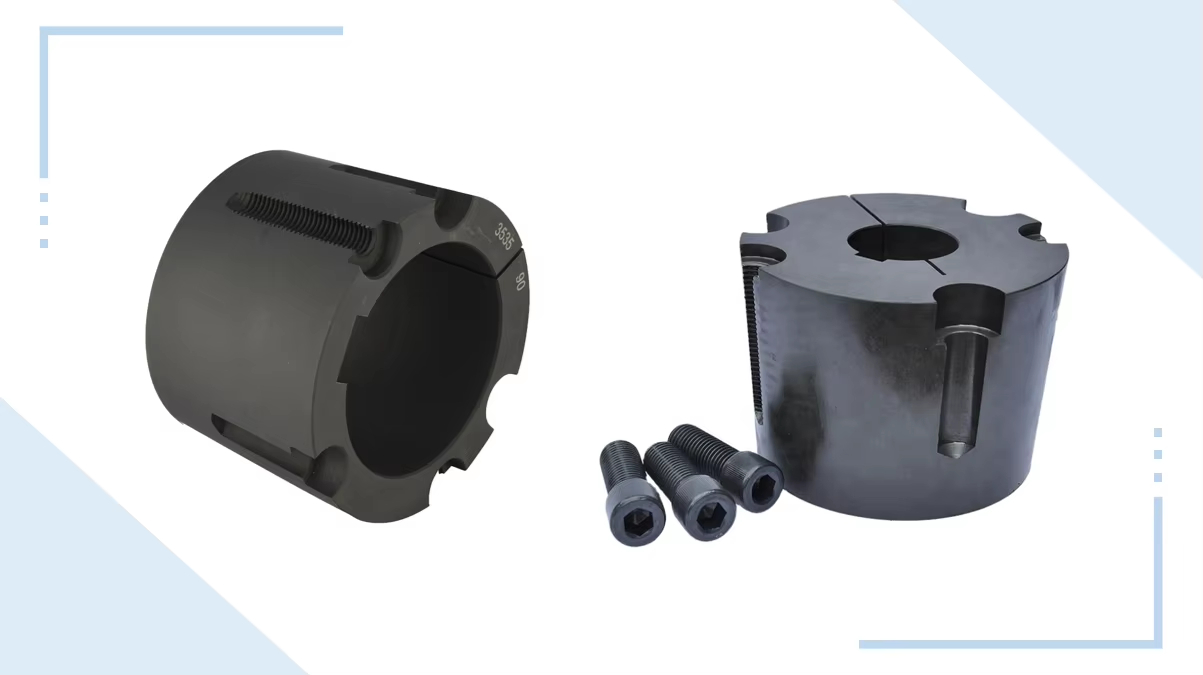

Standardne remenice s žljebovima koriste se zajedno s klinastim remenjem i drugim vrstama remenja kako je gore navedeno. Njegovi utori omogućuju precizno spajanje tako da nema klizanja tijekom rada.

Primjene: Može utjecati na industrijske strojeve, pumpe kao i kompresore

Značajke: Kapacitet sučelja s neograničenom kompatibilnošću s drugim zupčanicima, jeftiniji i jednostavan za nabavu.

1.2 Zupčasti remen V remenica

Remenica koja se koristi u razvodnom remenu ima užljebljene površine koje zahvaćaju utore stvorene u razvodnom remenu kako bi pomogle u kontroli gibanja.

Primjene: robotika, transportne trake, motori automobila

Značajke: visoki stupnjevi točnosti, nema proklizavanja kada je riječ o sinkronizaciji nekih aktivnosti.

1.3 Ravni pojas Sustav remenica

Koloturnice ravnog remena koriste se s ravnim remenom kada je brzina problem i kada se prenosi mali okretni moment.

Primjene: tekstilni strojevi, mali motori

Značajke: Praktičan za korištenje zbog svojih glatkih valjaka koji se mogu prilagoditi velikoj brzini.

1.4 Koloturnice s više utora

Izrađeni su za višerebraste remene koji imaju visok kapacitet prijenosa snage.

Primjene: sustavi vozila, uređaji za grijanje i hlađenje

Značajke: Povećan prijenos snage, smanjeno klizanje remena

2. Primjena remenica

Koloturnice su postale vrlo važne u mnogim industrijama zbog svoje pouzdanosti. Uobičajene primjene uključuju:

Industrijski strojevi: primijenjeno u tehnikama prijenosa, ventilatorima i primjeni pumpi

Automobili: Koristi se u alternatorima, vodenim pumpama kao i u opremi za klimatizaciju.

Poljoprivreda: Primjenjuje se u traktorima, kombajnima i sustavima za navodnjavanje.

Rudarstvo i vađenje kamena: Presudno za konusne i čeljusne drobilice i sita, kao i sustave dodavanja i transportera

3. Ključne prednosti remenica

Svestranost: Prikladno za različite vrste remena i sustava prijenosa snage.

Učinkovitost: Dizajn osigurava minimalni gubitak energije.

Izdržljivost: Snažan u primjenama s velikim opterećenjem i ekstremnim radnim uvjetima

Jednostavnost korištenja: mogućnost instalacije i zamjene.

4. Savjeti za održavanje remenica

4.1 Redoviti pregled

Prema potrebi podmažite i potražite znakove istrošenosti ili zamora remenica; pukotine ili deformacije remenica. Svaki problem treba biti u mogućnosti identificirati dovoljno rano kako bi se izbjegao potpuni kvar sustava.

4.2 Provjere poravnanja

Stoga je važno da remenice budu poravnate kako bi se spriječilo rano trošenje remena i postigla optimalna funkcija.

4.3 Ispravno podmazivanje

Nanesite odgovarajuće mazivo na ležajeve remenica kako biste smanjili habanje i povećali korištenje proizvoda.

4.4 Zatezanje remena

Održavajte zategnutost remena ispravnom kako ne bi skliznuli ili djelovali prekomjerno na remenicu.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

MN

MN

NE

NE

KK

KK

UZ

UZ

KY

KY

XH

XH