Welding is an essential profession in manufacturing. It is used to bond two pieces of metal to create strength and prevent separation. Welding requires specific tools and equipment to do the job correctly. A robotic assistant involves a mobile robot that uses tools such as mechanical arms to perform tasks like welding as in the MINYUE Ground rail welding workstation. This unique robot simply takes the precision out of welding so that welds are perfect every time. Thanks to this robot, manufacturers can rest assured that their products won't fall apart anytime soon.

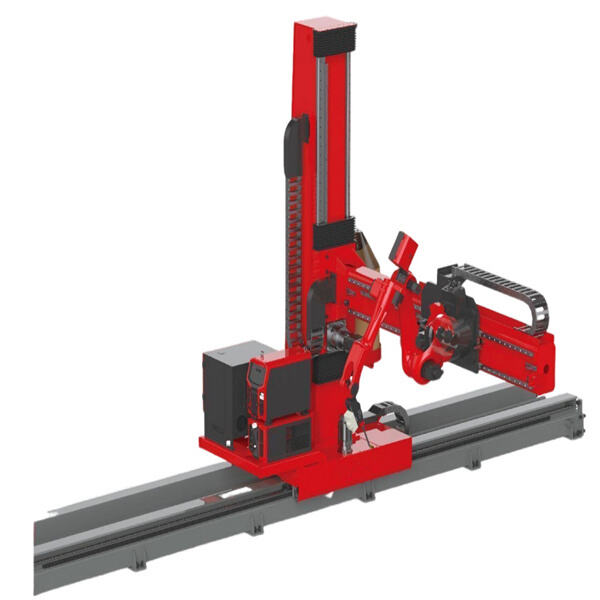

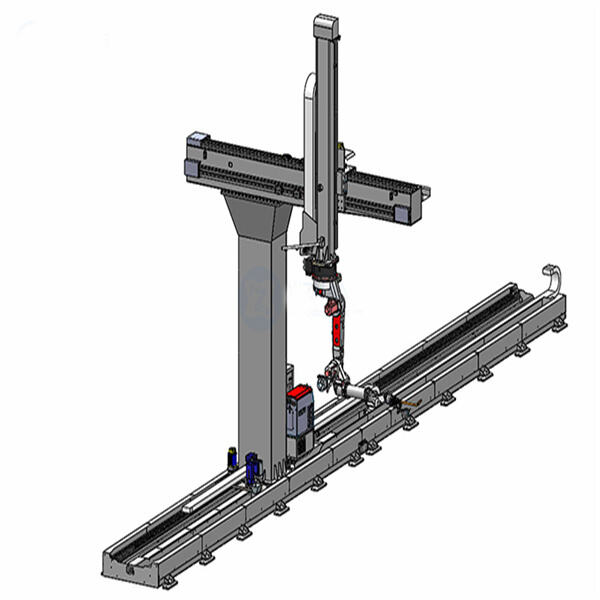

That's why the MINYUE 8-axis cantilever robot welding workstation is outfitted with the latest technology to ensure the welds are better than good. It has 8 movable parts that can move in different directions, which provide a specific solution for welding with high accuracy and speed. Its different movement ability allows it to enter different spaces to accomplish welding jobs that are difficult for other machines. All of this high-tech goodness comes in a small and compact workstation that is ideally suited for tighter spaces.

Productivity is key in the manufacturing process, that's where the MINYUE 8-axis cantilever robot welding workstation comes to improve that productivity. The system is highly flexible and can be easily used for various types of welding processes. MINYUE cantilever robot intelligent welding workstation flexibility helps companies save time and money. By utilizing this workstation, businesses can manufacture their products faster and produce greater amounts of work in a smaller duration of time. This added velocity will allow them to meet their deadlines and keep their customers satisfied.

Due to the importance of fitting the metal pieces accurately, precision is very important in the welding process. The MINYUE 8-axis cantilever robot welding workstation makes welding guesswork a thing of the past. It just moves precisely where it needs to and makes perfect welds each time. MINYUE welding robot precision is especially important to manufacturers that require high-quality welds to meet stringent standards. With this workstation, they will ensure that the products will be solid and robust.

MINYUE 8-axis cantilever robot welding workstation is the future of welding. MINYUE robotic spot welding advancements are revolutionizing how welding is performed — increasing efficiency and accuracy like never before. Utilising this workstation, businesses can own their industry and produce premium products for customers. So, they can always remain competitive and continue to expand.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.