Do campo da produção industrial aos sistemas de manuseio de materiais, tudo funciona bem, então você deve confiar no revestimento metálico. O cinto transportador de poliéster de grau industrial é um dos elementos importantes nessa área. Os transportadores de fábrica são aqueles cintos que apoiam as fábricas em segundo plano, facilitando o movimento das mercadorias de um processo para outro. Então, hoje, vamos explorar o mundo desses equipamentos poderosos e, especialmente, verificar suas melhoradas necessidades de energia.

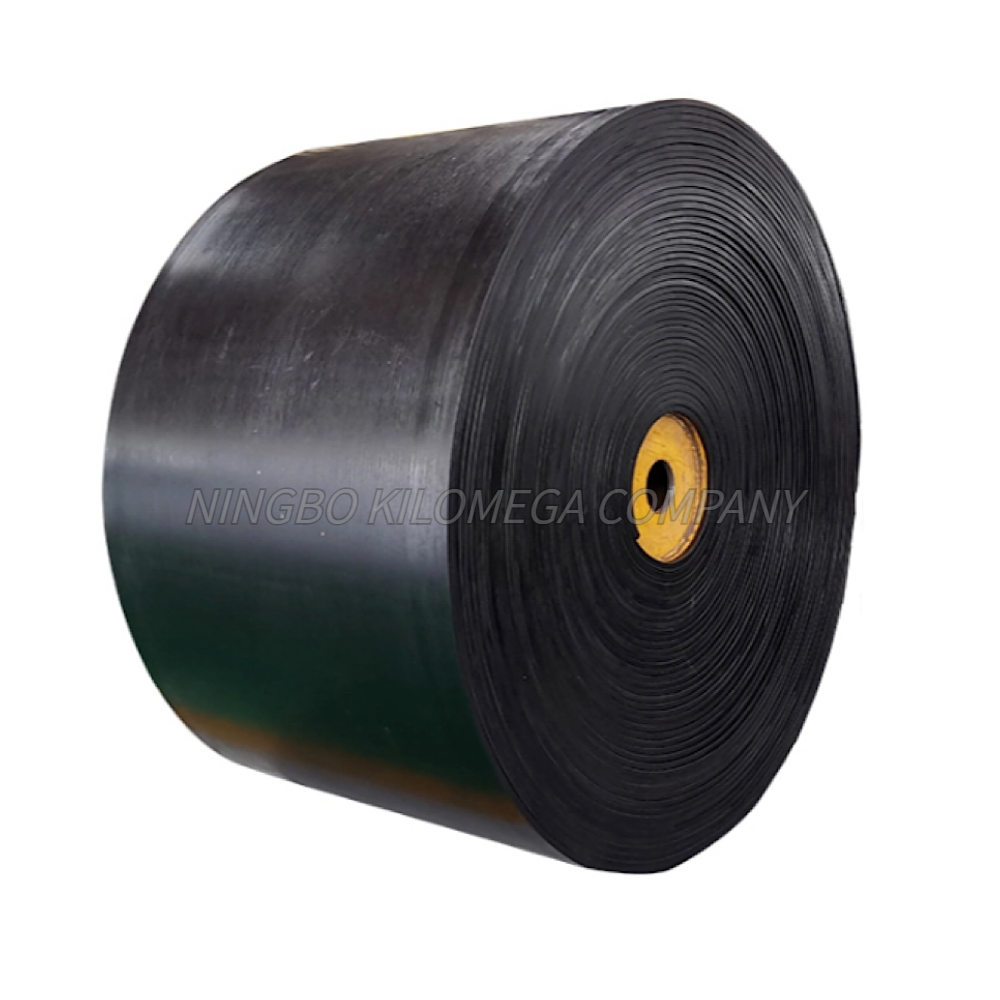

Nos locais industriais, os correias transportadoras de poliéster de grau industrial realmente mudaram a forma como os materiais são movidos na produção. Isso se deve ao fato de que elas oferecem força e uma transmissão de potência super otimizada, o que fez com que as correias se tornassem ferramentas muito importantes na indústria. Construídas com fibras de poliéster de alta resistência para um baixo alongamento e uma incrível resistência à tração. Além disso, elas foram revestidas e reforçadas de maneira especial para fortalecê-las, minimizando o tempo necessário para carregar novamente enquanto mantêm altos níveis de precisão. Além disso, essas correias possuem propriedades de força inovadoras que ajudam a proporcionar um desempenho eficiente diante de cargas em mudança. Isso não só economiza energia, mas também reduz os custos de manutenção no futuro.

Como resultado, nossas correias transportadoras de poliéster otimizadas para energia melhoram o desempenho com base no consumo de energia da sua fábrica.

E é na perfeita fluência de materiais entre diferentes pontos que reside o estado de potencial máximo de saída de uma fábrica. Uma das partes mais importantes nos cintos de poliéster otimizados para energia que apoiam a fornecer um desempenho consistente e confiável para este processo. Como Eles Ajudam: Sua resistência à tração e à abrasão significa que causam menos tempo de inatividade nas fábricas. Não só isso, esses cintos vêm com mecanismos de rastreamento embutidos para mantê-los centrados na trilha e evitar desalinhamentos que podem comprometer sua produtividade. Alguns desses cintos maximizarão a conservação de energia fornecendo uma transmissão eficiente de potência, tornando toda a planta mais eficiente em combustível e lucrativa.

Escolhendo Um Cinto Transportador Industrial de Poliéster Para Aplicações Pesadas - Um Guia Completo

Escolher a correia transportadora adequada para sua aplicação de alta resistência envolve não apenas encontrar um equilíbrio entre algo que é muito fraco para realizar um trabalho difícil e 'exagerar' ao usar algo mais forte do que o necessário, o que pode ser prejudicial. Exceção para ambos os extremos. Em primeiro lugar, você precisa determinar o que exatamente está sendo transportado - em termos de suas necessidades de suporte de carga e da materialologia. Essas correias podem precisar de capas mais grossas e revestimentos extras para ajudar a prolongar a vida útil da correia se os materiais forem abrasivos ou tiverem bordas afiadas. Em seguida, o ambiente em que você está operando deve ser considerado - umidade, calor ou produtos químicos podem exigir correias com melhores propriedades de resistência. Por fim, avaliar as necessidades de energia do sistema é importante; correias com membros de tensão otimizados e baixa resistência ao rolamento podem ajudar a melhorar a eficiência energética. Finalmente, priorize as correias que foram fabricadas para manutenção ou para serem substituídas imediatamente, pois isso pode gerar custos significativos de interrupção.

Em situações extremas, temos correias de poliéster de grau industrial

As correias transportadoras em ambientes industriais rigorosos estão sujeitas a temperaturas extremamente altas, solventes potentes e outras substâncias perigosas, além de líquidos contendo materiais abrasivos. Em ambientes como esses, as correias de poliéster de força industrial, que apresentam compostos especiais e camadas protetoras, são as melhores opções. Essa resistência inerente à umidade, óleo e abrasão, além da baixa retração geral, permite que esses produtos sejam usados em várias aplicações industriais, como mineração e britagem, processamento de alimentos e fabricação pesada, entre outros. Elas também são geralmente retardantes de chamas, adicionando uma segunda camada de segurança em algumas atmosferas voláteis.

Tecido Antiestático de Poliéster e Alta Durabilidade com Capacidades de Potência do Tipo Ecológico para Correias Transportadoras Industriais

Na indústria atual, a sustentabilidade tornou-se um dos valores centrais e as esteiras transportadoras não são exceção. As esteiras transportadoras de poliéster são opções ecológicas que têm um impacto mínimo no meio ambiente durante todo o seu ciclo de vida, desde a criação até o descarte. Elas também contêm material reciclado em seus produtos (20% para desempenho e durabilidade). Os recursos avançados de energia consomem menos energia overall, o que significa uma pegada de carbono menor. Além disso, essas esteiras foram projetadas para ter um longo tempo de serviço, o que ajuda a reduzir a geração de resíduos. Para avançar ainda mais em sua missão de reciclagem, alguns fabricantes oferecem programas de reciclagem para esteiras no fim de sua vida útil, em apoio à economia circular e ao gerenciamento responsável de resíduos.

O ponto principal é que as correias transportadoras industriais de poliéster são indispensáveis no ambiente de fabricação atual, proporcionando um aumento nas capacidades de potência que elevam a produtividade para uma produção duradoura e amiga do meio ambiente. É com o tipo correto de correia por aplicação que as indústrias podem otimizar seus processos, sobreviver em ambientes extremos e contribuir para metas ambientais. À medida que a tecnologia melhora, essas correias irão avançar ainda mais, não apenas como uma alternativa eficiente no manuseio de materiais, mas também como uma solução sustentável para isso.

Índice

- Como resultado, nossas correias transportadoras de poliéster otimizadas para energia melhoram o desempenho com base no consumo de energia da sua fábrica.

- Escolhendo Um Cinto Transportador Industrial de Poliéster Para Aplicações Pesadas - Um Guia Completo

- Em situações extremas, temos correias de poliéster de grau industrial

- Tecido Antiestático de Poliéster e Alta Durabilidade com Capacidades de Potência do Tipo Ecológico para Correias Transportadoras Industriais

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

MN

MN

NE

NE

KK

KK

UZ

UZ

KY

KY

XH

XH